Contents

- Best CO2 Leak Detector

- What is a CO2 leak gas detector?

- The Importance of CO2 Leak Detection

- CO2 Leak Hazards

- Wall Mounted CO2 Leak Detectors

- CO2 Leak Human Dangers

- CO2 FUN FACTS

- Why are CO2 leak detectors important in industries?

- What are the main causes of CO2 leaks in systems?

- What are Safe and Permissible Levels of Carbon Dioxide in Air?

- Is CO2 lighter or heavier than air?

- How does a CO2 leak detector work?

- Where should a CO2 leak detector be placed?

- Handheld CO2 Leak Detectors

- Is CO2 Dangerous?

- Is it CO or CO2? What’s the difference?

- Who Uses a CO2 Leak Detector?

- What Does CO2 Gas Smell Like?

- How often should I test or calibrate my CO2 leak detector?

- Will a CO2 Gas Leak set off Carbon Monoxide Detector?

- How Should I Store my CO2 Leak Detector?

- Difference Between CO2 and CO Leak Detectors

- Where to Place a CO2 Leak Detector

- Is CO2 harmful to humans?

- What are the side effects of a CO2 leak?

- Footnotes

- How to Test for a CO2 Gas Leak?

- Conclusion

- The Author

Best CO2 Leak Detector

CO2 Leak Detection is crucial for ensuring workplace, personal, employee, and business safety. CO2 leaks can lead to oxygen depletion and can be fatal if not detected and addressed promptly. CO2 Leak Detectors play a vital role in early detection. CO2 leak detectors are designed to detect and alert the presence of CO2 gas in the environment. They provide an early warning system, allowing for prompt action to mitigate the leak and ensure the safety of individuals in the area.

| ✅ Pros | ☢️ Cons |

| ✅ CO2 Leak Detectors are sensitive and find leaks to prevent oxygen depletion | ☢️ CO2 leaks are very dangerous as it can accumulate displace oxygen |

| ✅ CO2 Leak Detectors cost between $700 to $3000 | ☢️ CO2 is a heavy gas and can displace oxygen in confined spaces and suffocate humans |

| ☢️ CO2 leaks are very dangerous as it can accumulate and displace oxygen | ☢️ CO2 Leak Detectors do not detector carbon monoxide gas |

| ✅ CO2 Leak Detectors are made with NDIR sensors lasting up to 10 years | ☢️ CO2 cannot be detected by human faculties and a CO2 detector must be used |

What is a CO2 leak gas detector?

A CO2 leak gas detector is a device used to detect leaks of carbon dioxide gas. It is particularly essential in industries such as restaurants, beverage industries, indoor agriculture, and breweries where CO2 hazards are common. There are many types of CO2 Detectors which include:

CO2 Detectors for Air Quality Monitoring

CO2 for Handheld Gas Leak Detection

CO2 for Continuous Indoor Monitoring and Occupational Safety

CO2 Analyzer for Headspace and MAP food analysis

CO2 Personal Detectors for Personal Safety (PPE Applications)

CO2 Controllers for Hydroponics and Greenhouse Control

The Importance of CO2 Leak Detection

CO2 leak detection plays a vital role in maintaining safety standards. Detecting CO2 leaks is crucial for preventing potential hazards and ensuring a safe environment. By using advanced detection technology, such as a CO2 leak detector, businesses and individuals can identify leaks promptly and take appropriate measures to mitigate any potential risks.

Unlike traditional leak detection methods, CO2 leak detectors offer a reliable, efficient, and cost-effective solution. They provide real-time monitoring and can be easily integrated into existing safety systems. With their ability to detect leaks in various environments, including industrial settings, laboratories, and commercial spaces, CO2 leak detectors are essential tools for maintaining safety standards.

CO2 leak detectors have undergone significant advancements since Non-Dispersive infrared (NDIR) sensor Technologies have become commonplace and very affordable.

CO2 Leak Hazards

CO2 leaks can occur in various settings, such as industrial facilities, breweries, and storage facilities. They also provide an indispensable layer of protection in various industries that handle carbon dioxide, including oil and gas, manufacturing, and storage facilities. The release of carbon dioxide into confined spaces can displace oxygen, leading to asphyxiation and even fatalities. Additionally, high concentrations of CO2 can cause dizziness, confusion, and nausea, exacerbating the risk.

Understanding CO2 leak hazards goes beyond mere awareness of the risk. It entails being equipped with the necessary tools and knowledge to mitigate and prevent such incidents. By implementing strict safety protocols and utilizing technologies like the CO2 Leak Detector, companies can ensure the safety of their workers, the general public, and the environment.

In a real-life example, a local brewery experienced a CO2 leak, endangering the staff and customers. However, due to their commitment to safety, they had installed a CO2 Leak Detector. Once the detector identified abnormal carbon dioxide levels, an immediate evacuation was initiated, preventing any casualties. This incident highlighted the importance of understanding CO2 leak hazards and having the appropriate measures in place to safeguard against them.

To enhance the effectiveness of CO2 leak detectors, it is essential to conduct regular maintenance and calibrations. This ensures that the detectors remain accurate and reliable, providing accurate readings and timely alerts. Additionally, fostering a culture of safety awareness and providing proper training to personnel handling CO2-containing systems further strengthens the role of leak detectors. By adhering to recommended practices and regulations, organizations can optimize the performance of these detectors and minimize the potential risks associated with CO2 leakage.

Wall Mounted CO2 Leak Detectors

Permanent CO2 leak detectors are installed in facilities to provide continuous monitoring. Some key considerations include:

- Location: Install detectors near potential emission sources, such as equipment or storage areas.

- Level and Spread: CO2 is heavy, so place them lower to pick up CO2 faster, yet high enough where you can see the digital screen, can maintain them, and where they will not be damaged.

- Interference: Avoid placing detectors near ventilation systems or other devices that may affect their detection performance via dilution or microplume effects.

- Regular Maintenance: Ensure detectors are regularly inspected, calibrated, and tested to guarantee optimal performance.

- Integration with Alarm Systems: Connect detectors to alarm systems for immediate alerts and swift response in case of CO2 leaks.

- Education and Training: Provide training to employees on the importance of detector placement and how to respond to leak incidents.

CO2 Leak Human Dangers

The consequences of CO2 leaks can include asphyxiation, respiratory problems, and even death for individuals exposed to high concentrations of carbon dioxide.

CO2 FUN FACTS

- ✅ A CO2 leak detector is essential for industries such as restaurants, beverage industries, indoor agriculture, and breweries.

- ✅ Carbon dioxide leaks can be deadly even when normal oxygen levels are present.

- ✅ CO2 leak detectors are designed to detect and locate potential CO2 leaks in systems such as commercial refrigeration, soda dispensers, indoor grow facilities, brewery fermentation tanks, and draft beer coolers.

- ✅ CO2 leaks can be caused by failure to service and maintain systems, as well as damage caused through improper or repetitive use.

- ✅ CO2 leak detectors use a non-dispersive infrared sensor (NDIR) to measure carbon dioxide levels and pinpoint potential leak points.

Why are CO2 leak detectors important in industries?

CO2 leak detectors are crucial in industries because carbon dioxide leaks can be deadly even when normal oxygen levels are present. Industries that use CO2, such as commercial refrigeration systems, restaurant soda dispensers, indoor grow facilities, brewery fermentation tanks, and draft beer coolers, often contain high concentrations of CO2 where leaks can occur.

What are the main causes of CO2 leaks in systems?

The two main issues that can cause leaks in CO2 systems are failure to service and maintain systems, and damage caused through improper or repetitive use. This includes improperly installed beverage systems, CO2 cylinders or bulk tanks that are not properly vented, leaking fittings, connections, piping/tubing, leaking carbonators, syrup pumps, and leaking beer keg couplers, and equipment.

What are Safe and Permissible Levels of Carbon Dioxide in Air?

- California State Assembly Bill AB841 requires classrooms to monitor CO2 and alarm at 1,100 ppm

- American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) recommends indoor CO2 concentrations be maintained below 1,000 ppm in schools and 800 ppm in offices

- Washington State requires CO2 monitoring in restaurants, alarming at 450 ppm

- German Federal Environment Agency recommends classroom and office CO2 levels below 1,000 ppm

- Occupational Safety and Health (OSHA) and the National Institute for Occupational Safety and Health (NIOSH) have set a 5,000 ppm 8-hour TWA limit

- American Conference of Governmental Industrial Hygienists (ACGIH) has set a 5,000 ppm 8-hour TWA limit and a ceiling exposure limit of 30,000 ppm for a 10-minute period

- Exposure to CO2 levels of 40,000 ppm is immediately dangerous to life or health.

Is CO2 lighter or heavier than air?

Carbon dioxide is heavier than air, weighing approximately 1.5 times more. This can be observed when dry ice is utilized to create the “dancing on a clouds” effect at weddings. The carbon dioxide clouds remain close to the ground due to the fact that CO2 is heavier than air.

How does a CO2 leak detector work?

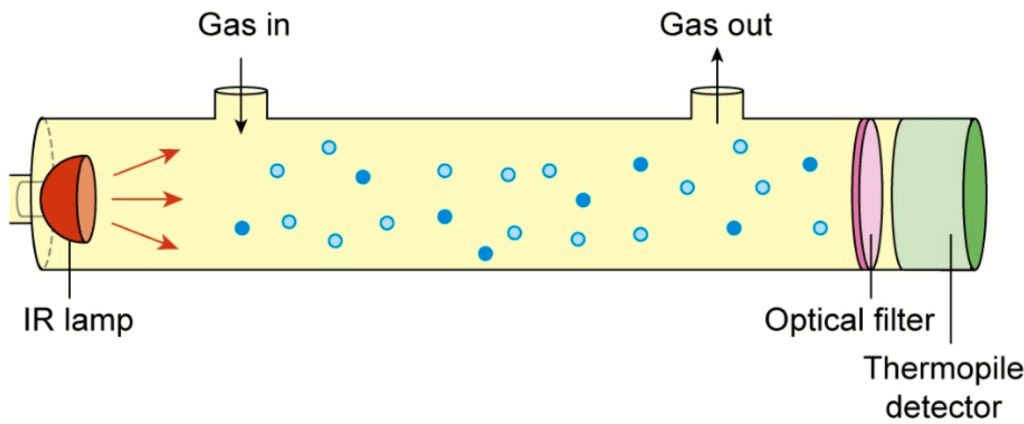

A CO2 leak detector works by measuring carbon dioxide instantly through a sampling tube. It utilizes a non-dispersive infrared sensor (NDIR) for accurate detection of even the smallest potential leak points.

The detector emits a specific wavelength of infrared light (typically between 4.2 to 4.4 micrometers) from an infrared light source. Carbon dioxide molecules selectively absorb this wavelength.

To collect a sample of the surrounding air or gas mixture, the detector uses an inlet or sampling port. The CO2 Leak Detector has a built-in pump that forces air into the chamber for faster leak detection.

The infrared sensor, made of pyroelectric or thermopile material, detects the infrared light after it interacts with the gas sample.

When the infrared light passes through the gas sample, carbon dioxide molecules absorb some of the light at the specific wavelength emitted by the light source. The amount of absorbed light is directly proportional to the concentration of carbon dioxide present in the sample.

The infrared sensor measures the intensity of the light that has passed through the gas sample and converts it into an electrical signal. The magnitude of the electrical signal corresponds to the amount of absorbed light and indicates the concentration of carbon dioxide in the environment.

The CO2 leak detector is programmed with a predetermined threshold or alarm level for carbon dioxide concentration. If the detected concentration exceeds this threshold, the detector triggers an audible and/or visual alarm to alert individuals of the potential CO2 leak.

Where should a CO2 leak detector be placed?

A CO2 leak detector should be placed in any indoor confined space where CO2 is being produced, used, or stored. For example, in breweries, areas that store, create, or use CO2 provide more opportunities for leaks. It is essential to regularly check CO2 distribution systems, such as walk-in coolers, for potential leaks.

Handheld CO2 Leak Detectors

Handheld CO2 leak detectors are portable and user-friendly, making them an ideal choice for users who need to monitor CO2 levels in different locations frequently. These detectors often feature advanced NDIR (Non-Dispersive Infrared) sensors that provide accurate and reliable tracking of even the smallest CO2 leaks.

Another type of CO2 leak detector is the plug-in detector, which is designed for stationary use. These detectors are often installed in rooms with potential CO2 leaks, continuously monitoring the CO2 levels and alerting users when the concentration reaches an unsafe threshold. While these detectors may not offer the portability of handheld devices, they provide constant protection in a fixed location.

Is CO2 Dangerous?

Carbon dioxide (CO2) is a naturally occurring gas that is essential for many life processes. However, high concentrations of CO2 can pose serious health risks. When CO2 levels increase to 3-5% in an enclosed area, it can become dangerous to human health, causing symptoms such as headaches, loss of concentration, and lower test scores in students.

In some cases, a CO2 leak from storage tanks, cylinders, or piping can quickly raise indoor CO2 levels to hazardous concentrations. To mitigate these risks, proper ventilation and emergency alarm systems are recommended source. A CO2 detector can also be used to detect CO2 levels and alert occupants to potential dangers.

Is it CO or CO2? What’s the difference?

It’s important to note that CO2 should not be confused with carbon monoxide (CO), an invisible, odorless, and poisonous gas that is produced from the incomplete combustion of fuels containing carbon, such as wood, gas, and propane. Carbon monoxide can be deadly, even at low levels, and requires a different type of detector for proper monitoring.

Propane, on the other hand, is a flammable gas used commonly for heating and cooking. Unlike CO2 or carbon monoxide, propane has a distinct odor, making leaks easier to identify. Propane gas detectors are also available and can help detect leaks before they become hazardous.

In conclusion, while CO2 is an essential component of life on Earth, elevated concentrations can be harmful. It is important to ensure proper ventilation and safety measures are in place, such as CO2 leak detectors, to protect against the potential hazards of CO2, carbon monoxide, and propane gases.

Who Uses a CO2 Leak Detector?

CO2 leak detectors are essential tools used by various industries and professionals to ensure safety and prevent costly damage. Some of the primary users of CO2 leak detectors include:

- Refrigeration Technicians: Professionals working with refrigeration systems frequently rely on CO2 leak detectors to identify and fix leaks in CO2-based refrigeration applications. As CO2 is increasingly being utilized as a refrigerant due to its eco-friendliness, proper leak detection measures are crucial to maintaining safe working conditions and compliance with safety standards (source).

- HVAC Technicians: CO2 leak detectors are used by HVAC technicians to monitor and maintain a safe indoor air quality level by detecting any CO2 leaks in heating, ventilation, and air conditioning systems. Identifying and addressing leaks in these systems can improve energy efficiency and protect the health of building occupants.

- Firefighters and First Responders: Elevated CO2 levels can pose significant risks in emergency situations, such as fires and other hazardous events. As a result, firefighters and first responders often utilize CO2 leak detectors to ensure a safe environment when addressing emergencies.

- Industrial Plant Operators: Industrial facilities that involve the production, storage, or use of CO2 need accurate leak detection systems to ensure safety and minimize losses. CO2 leak detectors play a vital role in identifying potential leaks, helping operators to take prompt action and maintain safety standards.

- Food and Beverage Industry: CO2 is commonly used in the food and beverage industry for carbonation and preservation processes. CO2 leak detectors can help ensure the safety and quality of food products by identifying potential leaks in carbonation systems, CO2 storage, and other related areas (source).

When setting up your CO2 leak detector, be sure to place it near potential leak sources, such as gas cylinders, valves, or pipelines. Proper placement is crucial for effective leak detection and ensuring the safety of everyone in the area.

What Does CO2 Gas Smell Like?

Carbon dioxide (CO2) is a colorless, odorless, and tasteless gas that is naturally present in the atmosphere. CO2 gas is produced from various sources, such as the combustion of fossil fuels, respiration of living organisms, and decay of organic matter. However, when CO2 levels exceed safe concentrations, it becomes a potential health hazard for humans and animals.

Although CO2 itself does not have a noticeable smell, it is almost always emitted alongside different gases that have distinct odors. For example, when CO2 is released during the combustion of fossil fuels, it is often accompanied by other gaseous by-products like sulfur dioxide and nitrogen oxides, which can have a pungent or unpleasant smell.

In some cases, a CO2 gas leak may be mistaken for a natural gas leak due to the odor. Natural gas providers often add a chemical called mercaptan, which gives the gas its characteristic “rotten egg” smell. This is done to facilitate the detection of leaks, as natural gas is otherwise also odorless. However, it is crucial to differentiate between CO2 gas leaks and natural gas leaks, as the latter is flammable and poses a much greater immediate risk.

How often should I test or calibrate my CO2 leak detector?

The Industrial Safety Equipment Association (ISEA) recommends verifying the operational capability of CO2 leak detectors before each day’s use, with additional testing conducted as necessary 1. So daily bump testing is recommended. Calibration should be performed every 6 to 12 months.

By diligently calibrating and maintaining your CO2 leak detector, you can substantially reduce the risk of inaccurate readings and ensure a safer environment. Remember to follow the manufacturer’s guidelines and recommendations to maximize the performance and longevity of your CO2 leak detector.

Will a CO2 Gas Leak set off Carbon Monoxide Detector?

A carbon monoxide detector is unable to detect CO2 gas leaks because these devices focus on sensing CO levels in the air. CO detectors use specific electrochemical, infrared, or metal oxide semiconductor (MOS) sensors that are calibrated to react to the presence of carbon monoxide, but these sensors do not respond to carbon dioxide. This is due to the differing chemical and physical properties of the two gases. For instance, CO has a strong affinity for binding with hemoglobin in the blood, leading to oxygen deprivation, while CO2 does not have the same effect.

How Should I Store my CO2 Leak Detector?

Proper storage of your CO2 leak detector is essential to ensure its accuracy and longevity. By following a few simple guidelines, you can help maintain the performance of your device and keep it in optimal working condition.

First, always store the leak detector in a clean, dry location to prevent any potential damage from moisture or dust. It is also important to protect your device from extreme temperatures, as these can harm its delicate components. Make sure to keep your CO2 leak detector away from direct sunlight, heat sources, or freezing conditions. A temperature-controlled environment, such as room temperature, is best for storage.

Difference Between CO2 and CO Leak Detectors

CO2 is a natural gas composed of one carbon atom and two oxygen atoms. It is released through human and animal respiration, combustion of fossil fuels and wood, and fermentation processes among other sources. CO2 detectors are mainly used in industries, homes, or other indoor environments where ventilation is insufficient or CO2 production is significant. These detectors monitor CO2 concentration levels and check if the area is within the acceptable range of 30,000 ppm for short-term exposure and 5,000 ppm for long-term exposure.

On the other hand, CO is a toxic gas with one carbon atom and one oxygen atom. It is produced during incomplete combustion of carbon-based fuels, which can happen in various appliances like furnaces, generators, or vehicles with internal combustion engines. CO is harmful to humans because it can bind to hemoglobin in the blood, reducing the oxygen-carrying capacity of red blood cells. CO detectors are designed to monitor CO levels, sound an alarm, and provide an early warning when the levels become dangerous.

Where to Place a CO2 Leak Detector

Placing a CO2 leak detector in the right location is crucial for accurately detecting leaks and ensuring the safety of the occupants in your home or facility. There are a few key aspects to consider when determining the best placement for a CO2 leak detector.

Firstly, install the detectors near potential sources of CO2 leakage. This includes areas with fuel-burning appliances such as gas stoves, water heaters, and furnaces. It is also wise to place detectors near attached garages, as automobiles can emit CO2 when they run.

CO2 is heavier than air, so it is essential to install detectors low to the ground. A good rule of thumb is to place them within 18 inches (45 cm) of the floor. This ensures that the detector will be able to pick up any CO2 gas accumulating near the ground.

In large commercial or industrial settings, CO2 detectors should be evenly distributed throughout the space. This ensures comprehensive coverage and helps identify leaks in all areas. If the space is particularly large or complex in layout, consider consulting with a professional to determine the best placement strategy.

Is CO2 harmful to humans?

Carbon dioxide (CO2) is a naturally occurring gas that is present in the air we breathe. However, at high concentrations, it can be harmful to humans. The severity of the symptoms depends on the concentration of CO2 and the duration of exposure1.

At low concentrations (around 5,000 parts per million, or ppm), CO2 can cause discomfort, headaches, and dizziness2. As the concentration of CO2 increases, more severe symptoms can occur, such as difficulty breathing, confusion, and even loss of consciousness3.

It is important to note that CO2 can become deadly even when normal oxygen levels are present4. This is because CO2 displaces oxygen in the air, causing the percentage of available oxygen to decrease. High levels of CO2 can accumulate quickly and without warning, resulting in serious health effects or death5.

CO2 leak detectors are essential for monitoring areas where CO2 may accumulate and help to prevent exposure to harmful concentrations. These detectors can initiate an emergency alarm system to alert occupants when CO2 levels exceed safe thresholds6.

| 🦜 FUN FACT TIME 🦜 |

| Carbon dioxide gas is that it is the gas that gives carbonated drinks their fizz. When carbon dioxide is dissolved in water under high pressure, it forms carbonic acid, which gives the drink its tangy taste and bubbles. |

What are the side effects of a CO2 leak?

Carbon dioxide (CO2) leaks can pose certain risks to human health if they occur in confined spaces and are not detected in time. The effects of a CO2 leak can range from mild symptoms to severe health problems, depending on the concentration of CO2 in the air.

At lower levels, exposure to CO2 may lead to mild symptoms such as headache and drowsiness. These initial symptoms can easily be ignored or mistaken for other issues, which emphasizes the importance of a reliable CO2 leak detector in preventing further exposure. As the concentration of CO2 increases, more severe effects can be experienced, including rapid breathing, confusion, increased cardiac output, elevated blood pressure, and increased arrhythmias1.

If CO2 levels rise significantly and the air becomes oxygen-depleted, it can lead to a life-threatening situation. This is because CO2 is 1.5 times heavier than air, and leaking CO2 can accumulate at floor level in poorly ventilated or unventilated rooms, causing hazardous concentrations2.

Additionally, prolonged exposure to high levels of CO2 can result in a condition called hypercapnia. This occurs when there is an excessive amount of CO2 in the bloodstream, causing symptoms such as headaches, confusion, flushed skin, increased heart rate, and elevated blood pressure3. If left unchecked, hypercapnia can lead to respiratory failure and even death.

Preventing CO2 leaks and addressing them quickly is essential, as the immediate and long-term side effects of exposure can have serious consequences on human health. It is important to invest in a reliable CO2 leak detector that can help to detect the presence of unusually high concentrations of CO2 and alert occupants of the risk. This, combined with proper ventilation and awareness of the dangers of CO2, can help to minimize side effects and prevent tragic outcomes.

Footnotes

- (https://www.fsis.usda.gov/sites/default/files/media_file/2020-08/Carbon-Dioxide.pdf) ↩

- (https://dfs.dps.mo.gov/safetytips/carbondioxide.php) ↩

- (https://www.iccsafe.org/building-safety-journal/bsj-technical/co2-standards-do-you-know-the-dangers-of-carbon-dioxide/) ↩

How to Test for a CO2 Gas Leak?

To ensure safety when conducting tests, it’s important to be in a well-ventilated area or wear appropriate personal protective equipment (PPE) if necessary. If you suspect a significant CO2 leak or experience symptoms of carbon dioxide poisoning, evacuate the area immediately and seek fresh air. Remember that CO2 is heavier than air, so extra precautions should be taken in shafts or confined spaces.

Using a CO2 leak detector can help pinpoint the location of any leaks. Check gas lines, CO2 cylinders, junctions, and connectors for potential leaks.

Allow the CO2 detector enough time to sample the air and provide accurate readings. We recommend moving 1 inch per 2 seconds. Monitor the detector’s display or indicators for any changes in carbon dioxide levels. If the detector has an alarm function, ensure that it is activated and set to an appropriate threshold.

If a leak is found, take note of its location and tag it. Ensure that the breathable air does not exceed 5000ppm (otherwise evacuate) and address the leakage with an appropriate engineer or technician.

Conclusion

A CO2 leak detector is specifically designed to locate CO2 gas leaks in gas lines and connections. These detectors help to identify and pinpoint potential CO2 leaks before they become a health hazard, as CO2 can accumulate and reduce the oxygen in an indoor space.

A CO2 leak detector should be equipped with a pinpoint probe, a built-in pump (to increase detection speed), and a display that shows CO2 concentration in ppm.

When using a CO2 gas leak detector, it’s important to be patient and slow as it can take some time to get an accurate reading.

The Author

Dr. Koz resides in the Palos Verdes Peninsula in Los Angeles, California. He is a subject matter expert on gas leak detectors, gas sensor technology, gas detectors, gas meters, and gas analyzers. He has been designing, building, manufacturing, and testing toxic gas detection systems for over 20 years. Every day is a blessing for Dr. Koz. He loves to help customers solve their unique problems.

Email: drkoz@gasleakdetector.com

Phone: +1 424-341-3886