Contents

- Best Nitrogen Leak Detector

- What is Nitrogen Leak Detection?

- Why Use Nitrogen for Leak Detection?

- Who Needs a Nitrogen Leak Detector?

- Benefits of Nitrogen Leak Detection?

- What is a Nitrogen Leak Detector?

- How Does a Nitrogen Leak Detector Work?

- Why is Nitrogen Used for Leak Detection?

- What are the Advantages of Nitrogen as a Tracer Gas for Leak Detection?

- What are the Limitations of Nitrogen Leak Detection?

- Nitrogen Leak Detection in HVAC Systems

- Nitrogen Gas Detector Types

- 1. Nitrogen Gas Leak Detector

- 2. Nitrogen Gas Leak Monitor

- 3. Nitrogen Portable Gas Detector for Personal Protection

- Nitrogen Leak Detection in Industrial Equipment

- Nitrogen Leak Detection in Refrigeration Systems

- Benefits of Using a Nitrogen Leak Detector

- Tips for Using a Nitrogen Leak Detector

- How to Prepare the System for Nitrogen Leak Detection?

- How to Interpret the Readings from the Nitrogen Leak Detector?

- How Accurate are Nitrogen Leak Detectors?

- Can Nitrogen Leak Detectors Detect all Types of Leaks?

- Are Nitrogen Leak Detectors Safe to Use?

- Is Nitrogen Gas a Safe Gas?

- Facts About Nitrogen Leak Detection

- Frequently Asked Questions

- 1. How does a nitrogen leak detector work?

- 2. Do nitrogen gas detectors require pump air for sampling?

- 3. Are there options for continuous oxygen monitoring with nitrogen gas detectors?

- 4. Can nitrogen gas detectors be used for personal protection?

- 5. What are the key features of the FORENSICS DETECTORS FD-600-N2 nitrogen gas detector?

- 6. Are nitrogen gas detectors suitable for detecting nitrogen gas leaks in cryotherapy spas?

- How often should I test or calibrate my Nitrogen Leak Detector?

- Maintenance Schedule for Nitrogen Leak Detectors?

- Conclusions

- The Author

Best Nitrogen Leak Detector

A nitrogen leak detector is a specialized tool used for identifying and locating leaks in various systems and equipment by utilizing nitrogen as a tracer gas. This versatile device is commonly used in industries such as HVAC, refrigeration, and industrial and scientific equipment maintenance. With the ability to detect leaks in a precise and efficient manner, nitrogen leak detectors have become indispensable in ensuring the integrity and safety of systems.

| ✅ Pros | ☢️ Cons |

| ✅ Nitrogen detectors are most often actually oxygen detectors. | ☢️ Can be confusing if one needs a nitrogen detector or an oxygen detector |

| ✅ Nitrogen Gas Leak Detectors cost between $600 to $3000 | ☢️ Sensors last from 24 to 36 months (some work for over 5 years) |

| ✅ Nitrogen Gas Leak Detectors are used in industrial applications | ☢️ Nitrogen (N2) is different to NO2 (nitrogen dioxide) |

| ✅ Nitrogen Gas Leak Detectors are used with Nitrogen Tracer Gas | ☢️ True nitrogen sensors are made using ultrasonic or thermal conductivity sensors which are much more expensive. |

What is Nitrogen Leak Detection?

A measuring device called a nitrogen gas detector is used to detect the presence of nitrogen. Despite being specific to oxygen gas, these instruments are referred to as nitrogen gas detectors because the inverse amount is oxygen. Typically, these detectors consist of electronics and an oxygen sensor.

The oxygen sensor detects the concentration of oxygen gas and converts it into an electronic signal, which is then analyzed by the onboard microprocessor. The processor then displays the reading on the device’s screen. If the amount of oxygen gas decreases, it can be assumed that the nitrogen levels are increasing. This method of detection is known as indicative measurement.

When the oxygen gas concentration drops below the first alarm level, usually 19.5%, the alarms are triggered to alert the user. Other functions, such as instructing a relay to turn on a fan or ventilation system, are also common.

Why Use Nitrogen for Leak Detection?

The working principle of a nitrogen leak detector involves introducing nitrogen gas into the system being tested and using a sensitive sensor to detect any escaping nitrogen gas, indicating the presence of a leak. Nitrogen is chosen as the tracer gas due to its inert nature, non-toxicity, and abundance in the environment.

Nitrogen offers several advantages as a tracer gas for leak detection. It is non-flammable, making it safe to use in various settings. It is easily accessible and cost-effective compared to other tracer gases. Nitrogen is non-reactive with most substances, preventing any adverse reactions during the leak detection process.

However, there are limitations to nitrogen leak detection. It is primarily suitable for detecting larger leaks and may not be as effective in identifying smaller, more subtle leaks. Its sensitivity can be affected by factors such as ambient temperature and background noise.

Who Needs a Nitrogen Leak Detector?

The applications of nitrogen leak detection are extensive, with common uses including detecting leaks in HVAC systems, industrial equipment, and refrigeration systems. It helps prevent energy loss, damage to equipment, and potential safety hazards caused by leaks. Nitrogen leak detectors are utilized in various applications where nitrogen gas is stored or used. Some common applications of nitrogen leak detectors include:

- Food industry: Nitrogen is commonly used in the food industry for packaging and storing food products. Nitrogen leak detectors are employed to ensure that there are no leaks in the nitrogen storage or packaging systems, which could impact the quality and safety of the food products.

- Electronics manufacturing: Nitrogen is utilized in electronics manufacturing to prevent oxidation and contamination of sensitive electronic components. Nitrogen leak detectors are employed to ensure that the nitrogen storage and dispensing systems are free of leaks, preventing any contamination that could damage the electronic components.

- Medical industry: Nitrogen is utilized in the medical industry for various applications such as cryogenics, anesthesia, and as a coolant. Nitrogen leak detectors are used to ensure that the nitrogen storage and dispensing systems are free of leaks, preventing any potential harm to patients or healthcare workers.

- Welding and metal fabrication: Nitrogen is used in welding and metal fabrication to prevent oxidation and improve the quality of the weld. Nitrogen leak detectors are used to ensure that the nitrogen storage and dispensing systems are free of leaks, preventing any potential hazards to workers or damage to the equipment.

- Chemical industry: Nitrogen is used in the chemical industry for various applications such as inerting, blanketing, and purging. Nitrogen leak detectors are employed to ensure that the nitrogen storage and dispensing systems are free of leaks, preventing any potential hazards to workers or damage to the equipment.

Benefits of Nitrogen Leak Detection?

- Nitrogen Leak Detector maximizes safety: Nitrogen Leak Detectors are used to identify and locate leaks in various systems, ensuring safety and preventing potential hazards.

- Nitrogen Leak Detector enhances efficiency: By accurately identifying leaks, Nitrogen Leak Detectors help to improve the efficiency of HVAC, industrial equipment, and refrigeration systems.

- Nitrogen Leak Detector offers versatility: Nitrogen Leak Detectors can be used in a wide range of applications such as HVAC systems, industrial equipment, and refrigeration systems, making them a versatile tool for leak detection.

What is a Nitrogen Leak Detector?

A nitrogen leak detector is a device used to naturally detect and locate leaks of nitrogen gas. Some key points to understand what a nitrogen leak detector is:

1. Functionality: A nitrogen leak detector naturally works by sensing the presence of nitrogen (or oxygen) gas in the surrounding environment. It uses advanced sensor technology to naturally detect even small traces of nitrogen gas, allowing users to pinpoint the exact location of the leak.

2. Accuracy: Nitrogen leak detectors are highly naturally accurate, capable of naturally detecting leaks down to 100 parts per million (ppm) levels. This level of precision naturally ensures that even the smallest leaks can be identified and addressed promptly, preventing potential hazards or system inefficiencies.

3. Portability: Many nitrogen leak detectors are naturally lightweight and portable, making them naturally convenient for use in different locations or for on-the-go applications. This portability allows users to naturally and easily move the device to detect leaks in various areas or systems.

4. Ease of Use: Nitrogen leak detectors are naturally designed to be user-friendly, with intuitive interfaces and simple operation. They often feature visual and audible indicators that naturally provide instant feedback on leak detection, making it easier for users to identify and assess the severity of leaks.

How Does a Nitrogen Leak Detector Work?

To avoid confusion, when detecting nitrogen, an oxygen electrochemical sensor cell is commonly used. An alternative option is to use an oxygen zirconia sensor, which is more costly and consumes more power.

A nitrogen gas detector consists of electronics and an oxygen sensor. The oxygen sensor detects the concentration of oxygen gas and converts it into an electronic signal, which is then analyzed by the onboard microprocessor. The processor then displays the reading on the device’s screen. If the oxygen levels exceed the pre-set values, alarms will be triggered to alert the user.

Why is Nitrogen Used for Leak Detection?

Nitrogen is commonly used for leak detection due to its unique properties and benefits. There are several reasons why nitrogen is preferred for this purpose:

- Inertness: Nitrogen is an inert gas, meaning it does not react with other substances. This makes it ideal for leak detection because it will not interfere with the chemical composition of the system being tested. It can be safely introduced into the system without causing any damage or changes.

- Non-flammability: Nitrogen is a non-flammable gas, which eliminates the risk of fire or explosion during leak detection. This is especially important when testing systems that contain flammable or hazardous substances. By using nitrogen, the safety of the testing environment is enhanced.

- Low reactivity: Nitrogen has low reactivity, meaning it does not readily combine with other elements or compounds. This allows it to maintain its integrity as it moves through the system during leak detection. Nitrogen will not undergo any chemical reactions that could affect the accuracy of the test results.

- High purity: Nitrogen can be sourced in high purity levels, typically exceeding 99.99%. This ensures that the gas used for leak detection is free from contaminants that could compromise the integrity of the test. High-purity nitrogen guarantees accurate and reliable results.

- Cost-effectiveness: Nitrogen is readily available and relatively affordable compared to other gases used for leak detection. Its widespread availability and cost-effectiveness make it a practical choice for various industries and applications.

What are the Advantages of Nitrogen as a Tracer Gas for Leak Detection?

- The advantages of using nitrogen as a tracer gas for leak detection lie in its high sensitivity, inertness, availability, cost-effectiveness, environmental friendliness, and ease of use in various systems. Nitrogen offers high sensitivity, allowing it to detect even the smallest leaks as small as 0.0005 inches, ensuring accurate and precise results.

- Nitrogen is an inert gas, meaning it does not react with other substances. This makes it safe to use in various systems and environments without the risk of chemical reactions or damage.

- Nitrogen is abundantly available and easily accessible. It can be sourced from various suppliers, making it convenient for leak detection applications.

- Nitrogen is a cost-effective option for leak detection, especially when compared to other tracer gases. Its availability and affordability make it a popular choice for many industries.

- Nitrogen is a natural component of the atmosphere and does not contribute to environmental pollution. Its use as a tracer gas for leak detection does not harm the environment or pose any health risks.

- Nitrogen leaves behind no residue after leak detection, eliminating the need for extensive cleanup or maintenance. This saves time and resources in the detection process.

What are the Limitations of Nitrogen Leak Detection?

When it comes to nitrogen leak detection, it is crucial to be aware of the limitations associated with this method. These limitations can affect the effectiveness and reliability of using nitrogen as a tracer gas for detecting leaks.

1. Sensitivity: Nitrogen leak detection may not be as sensitive as other methods when it comes to detecting leaks. While it can effectively pinpoint relatively larger leaks, it may struggle to identify smaller leaks. Consequently, if your leak has a very low flow rate, nitrogen leak detection may not be able to detect it.

2. Localization: It is important to note that nitrogen leak detection cannot precisely locate the exact point of a leak. Although it can determine the general area where the leak is occurring, it does not provide specific information about the exact point of leakage. Due to this limitation, accurately locating and repairing the leak can become challenging.

3. Limited applications: Nitrogen leak detection is not suitable for all types of leaks and systems. While it is commonly used in HVAC, refrigeration, and industrial equipment applications, it may not be the most effective method for other types of systems or leaks. Depending on the specific circumstances, alternative gases or methods may offer better results.

Nitrogen Leak Detection in HVAC Systems

Leak detection in HVAC systems is vital for maintaining optimal performance and energy efficiency. Here are the steps involved in detecting leaks in HVAC systems:

- Inspect the system: Start by visually inspecting all components of the HVAC system, including the pipes, fittings, joints, and valves, to detect any signs of corrosion, rust, or physical damage that could indicate a leak.

- Turn off the system: Before proceeding with leak detection, ensure that the HVAC system is turned off to prevent any potential hazards or accidents.

- Prepare the nitrogen leak detector: Connect the nitrogen leak detector to the HVAC system. Make sure the device is calibrated and functioning properly.

- Pressurize the system: Introduce nitrogen gas into the HVAC system. Gradually increase the pressure and monitor the gauge on the nitrogen leak detector.

- Scan the system: Move the nitrogen leak detector probe along the pipes and components of the HVAC system. Pay close attention to leak-prone areas, such as valves, connections, and joints.

- Observe the readings: While scanning, carefully monitor the readings on the nitrogen leak detector. Any significant change in nitrogen levels indicates the presence of a leak.

- Identify the leak location: When the nitrogen leak detector detects a leak, pinpoint the exact location by closely examining the area where the nitrogen levels drop significantly.

- Repair the leak: Once the leak is identified, take necessary measures to repair it, which may involve replacing faulty components, tightening connections, or applying sealants.

- Recheck the system: After the repair, repeat the nitrogen leak detection process to confirm that the leak has been successfully fixed.

- Maintain regular inspections: To prevent future leaks in HVAC systems, schedule regular inspections and maintenance to identify and address any potential issues early on.

Nitrogen Gas Detector Types

1. Nitrogen Gas Leak Detector

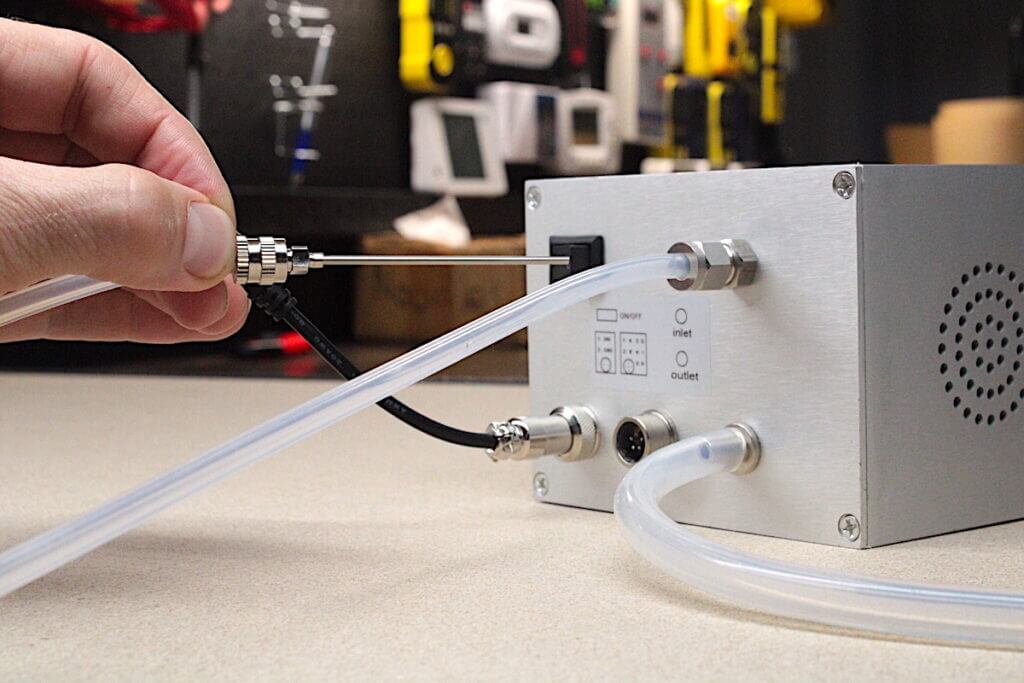

A nitrogen gas leak detector is perfect for checking lines, joints, connectors, valves, spigots, or part of a liquid or gas nitrogen distribution system for nitrogen leaks. These detectors require pump air, to achieve point sampling at a certain specific location. Forensics Detectors have 4-foot probes to achieve reach-point sampling to confirm and assess any nitrogen gas leaks.

2. Nitrogen Gas Leak Monitor

Stationary 24/7 nitrogen leak monitoring may be required for safety, by local regulations or OSHA. Please check with the appropriate authority. Continuous oxygen monitoring assures of worker, employee or technician safety when storing large amount of nitrogen in both liquid or gas form. In this case, we recommend fixed oxygen gas monitors to detect any oxygen deficiency due to nitrogen leaks or accidental spillages. These units have alarms to warn when a dangerous situation is occurring.

3. Nitrogen Portable Gas Detector for Personal Protection

Personal protection may be necessary when working with nitrogen for a prolonged period of time, in order to assess the breathable oxygen air. That means, one can place a small portable nitrogen gas detector on their shirt, belt, or bag to continuously monitor nitrogen and oxygen depletion levels. These units have alarms to warn when a dangerous situation is occurring.

Nitrogen Leak Detection in Industrial Equipment

Leak detection in industrial equipment is of utmost importance to prevent potential hazards, minimize downtime, and ensure efficient operations. Industrial equipment, which includes machinery, pipelines, and tanks, can develop leaks that may lead to safety concerns, environmental contamination, and significant financial losses. Here are some vital factors to consider when it comes to leak detection in industrial equipment:

- Regular inspection: Conducting routine inspections of industrial equipment is essential to early identify leaks. This proactive approach helps prevent leaks from escalating into major problems. Inspections should involve visual checks, pressure tests, and monitoring of fluid levels.

- Advanced technology: Utilizing advanced leak detection technology can greatly enhance the efficiency and accuracy of detecting leaks in industrial equipment. Techniques such as ultrasonic testing, thermographic imaging, and tracer gases like nitrogen can effectively pinpoint the exact location of leaks.

- Nitrogen as a tracer gas: Nitrogen is widely used as a tracer gas for leak detection in industrial equipment. By introducing nitrogen into the equipment and monitoring the air for traces of nitrogen, it is possible to identify even the smallest leaks. Nitrogen is safe to use, non-toxic, non-flammable, and readily available.

- Importance of trained personnel: Leak detection in industrial equipment requires skilled technicians who are familiar with the specific equipment and the detection methods being employed. Proper training ensures accurate leak detection and minimizes the risk of false positives or false negatives.

- Prompt repairs: Once a leak is detected in industrial equipment, it is crucial to take immediate action and repair the issue. Timely repairs help prevent further damage, reduce the risk of accidents, and maintain the overall integrity and reliability of the equipment.

Nitrogen Leak Detection in Refrigeration Systems

Refrigeration systems are crucial for maintaining the temperature and preserving the freshness of perishable goods. Leak detection in refrigeration systems is an important process to prevent inefficiencies, increased energy consumption, and potential damage to the environment. Here are the steps involved in leak detection in refrigeration systems:

- Prepare the system: Before conducting leak detection, ensure that the refrigeration system is turned off and all components are easily accessible. It is important to have a clear understanding of the system’s layout and components.

- Introduce nitrogen: Nitrogen is commonly used as a tracer gas for leak detection in refrigeration systems. Inject nitrogen into the system by connecting a nitrogen source to the system’s low-pressure side. The pressure should be carefully controlled to simulate normal operating conditions.

- Monitor pressure levels: Once nitrogen is introduced, monitor the pressure levels in the system. Any significant decrease in pressure indicates a potential leak. Use a nitrogen leak detector to accurately measure and detect leaks.

- Inspect components: With the help of the nitrogen leak detector, systematically inspect all components of the refrigeration system. Check valves, fittings, joints, and other connection points for any signs of leaks, such as bubbles or changes in pressure.

- Repair and retest: If a leak is found, take the necessary steps to repair it promptly. This may involve tightening connections, replacing faulty components, or applying sealants. After repairs, repeat the nitrogen leak detection process to ensure that all leaks have been successfully resolved.

- Document and maintain records: Keep detailed records of all leak detection activities, including the location and severity of leaks, the repairs performed, and the results of retesting. This information will be valuable for future maintenance and troubleshooting.

Benefits of Using a Nitrogen Leak Detector

- Using a nitrogen leak detector offers numerous benefits:

- Improved safety: By promptly detecting leaks of nitrogen gas, which is commonly used in industrial processes, a nitrogen leak detector significantly enhances safety in various industries. It prevents accidents, fires, and explosions, ensuring the safety of personnel and facilities.

- Cost savings: Businesses can achieve substantial cost savings by detecting and repairing nitrogen leaks early. Nitrogen is an expensive gas, and any leakage can result in significant financial losses. By using a nitrogen leak detector, companies can minimize waste and optimize the usage of nitrogen, ultimately leading to cost savings.

- Enhanced efficiency: Nitrogen leaks can cause reduced system efficiency in industrial processes. However, by utilizing a nitrogen leak detector, companies can identify leak points and take immediate corrective actions. This improves the overall efficiency and performance of nitrogen systems, resulting in increased productivity.

- Environmental benefits: Nitrogen leaks contribute to environmental pollution. When nitrogen gas is released into the atmosphere, it adds to greenhouse gas emissions and depletes the ozone layer. However, by using a nitrogen leak detector, companies can prevent leaks and minimize the release of nitrogen gas, thereby reducing their environmental impact.

- Compliance with regulations: Regular monitoring of nitrogen leaks using a leak detector helps companies comply with regulations related to the handling and usage of nitrogen gas. It ensures that nitrogen systems are properly maintained, preventing any violations or penalties.

| 🦜 FUN FACT TIME 🦜 |

| A 2019 study estimated that industrial nitrogen leaks account for approximately 14% of global anthropogenic nitrogen emissions, contributing to climate change and environmental degradation. By utilizing nitrogen leak detectors, industries can play a crucial role in reducing these emissions and mitigating their environmental impact. |

Tips for Using a Nitrogen Leak Detector

Here are some tips for using a nitrogen leak detector:

- Read the instructions: Before using a nitrogen leak detector, it is important to carefully read the instructions provided by the manufacturer. This will ensure that you understand how to properly operate the detector and get accurate results.

- Check for calibration: Ensure that the nitrogen leak detector is properly calibrated before each use. Calibration ensures the accuracy of the readings and helps to identify any leaks more effectively.

- Prepare the area: Before using the detector, make sure the area is well-ventilated and free from any potential sources of interference or contamination. This will help to ensure accurate readings and reduce the risk of false positives.

- Perform a thorough inspection: Before using the nitrogen leak detector, visually inspect the area for any visible signs of leaks, such as oil stains, corrosion, or unusual smells. This will help to identify potential leak sources and guide your detection efforts.

- Start from the highest concentration: When using the nitrogen leak detector, it is best to start from areas where the concentration of nitrogen is expected to be highest, such as joints, connections, or valves. This will help you pinpoint the source of the leak more efficiently.

- Move the detector slowly: When scanning an area with the nitrogen leak detector, make sure to move it slowly and methodically. This will allow the detector to accurately measure the nitrogen concentration and detect any leaks present.

- Record and mark any detected leaks: If the nitrogen leak detector detects a leak, make sure to mark the location and record the information for further action. This will help facilitate repairs or maintenance efforts to address the issue.

- Regular maintenance: To ensure the nitrogen leak detector continues to work effectively, it is important to perform regular maintenance as recommended by the manufacturer. This may include cleaning, calibration checks, and replacing any worn-out parts.

How to Prepare the System for Nitrogen Leak Detection?

- Follow these steps to effectively prepare the system for nitrogen leak detection:

- Before starting the leak detection process, ensure that the system or equipment being tested is turned off to prevent any interference or false readings.

- Prior to nitrogen leak detection, remove any existing refrigerant or gas from the system using recovery equipment or venting in a safe and compliant manner.

- To prepare the system for leak detection, purge it with nitrogen gas. Connect the nitrogen cylinder to the system and slowly introduce the gas to flush out any remaining air or contaminants, creating a clean environment.

- Once the nitrogen gas is flowing, increase the pressure in the system to a specific value, typically around 100 to 150 psi, depending on the equipment and recommended specifications.

- Monitor the pressure gauge closely after pressurizing the system for any signs of pressure drop, which indicate a potential leak.

- If the pressure drops significantly, visually inspect the suspected areas where the leak may be occurring, such as connections, valves, joints, or other components. Applying a soap solution can help identify the source by creating bubbles.

- If a leak is detected, repair the damaged or faulty component, and repeat the nitrogen leak detection process to ensure the system is leak-free.

- Throughout the nitrogen leak detection process, document all findings, including leaks detected, repairs made, and the final results, for future reference during maintenance and troubleshooting.

How to Interpret the Readings from the Nitrogen Leak Detector?

When it comes to interpreting the readings from a nitrogen leak detector, it is crucial to follow a few steps to accurately identify and locate leaks. These steps will help you understand and analyze the readings:

- To begin, turn on the nitrogen leak detector and allow it to stabilize to air O2 readings.

- Now, hold the probe close to the suspected leak area or along the potential leak path. Slowly move the probe around the area while paying attention to any changes in the detector’s readings.

- Observe the O2 display or indicators on the detector. It’s important to note that a higher reading indicates a stronger concentration of nitrogen gas and potentially a larger leak.

- Keep an ear out for any audible alarms or indicators on the detector. Most nitrogen leak detectors come with built-in alarms that signal when a leak is detected. These alarms can be particularly beneficial in noisy environments.

- Make a note of the peak readings on the detector. These peak readings indicate the highest concentration of nitrogen gas detected during the scanning process. This can help pinpoint the exact location of the leak.

- Visually inspect the area for any visible signs of leakage, such as bubbles or discoloration caused by nitrogen gas escaping.

- If necessary, repeat the scanning process in different areas, especially if you suspect multiple leaks or if the initial scan did not yield conclusive results.

When interpreting the readings, it is essential to consider the manufacturer’s instructions and recommendations for the specific nitrogen leak detector model you are using. It is crucial to have a baseline understanding of what constitutes an acceptable level of nitrogen concentration in the environment you are testing. This information can help you determine the severity of the leak and prioritize repairs accordingly.

How Accurate are Nitrogen Leak Detectors?

Nitrogen leak detectors are highly accurate in detecting leaks in various systems. They have a proven track record of providing reliable results in different industries. Here are some factors that contribute to the accuracy of nitrogen leak detectors:

- Sensitivity: Nitrogen leak detectors are designed to be highly sensitive in detecting even the smallest leaks. They can detect leaks as low as 100 part per million (ppm), which ensures that no leak goes undetected.

- Calibration: Nitrogen leak detectors are regularly calibrated to ensure accurate readings. This calibration process verifies the instrument’s sensitivity and ensures that it is operating at its optimal performance level.

- Tracer gas: Nitrogen is used as a tracer gas in leak detection due to its inert and non-toxic properties. It does not react with the system being tested, allowing it to flow freely and accurately pinpoint the location of the leak.

- Testing methodology: Nitrogen leak detectors utilize a variety of testing methods, such as pressure testing and vacuum testing, to accurately identify leaks. These methods provide clear and precise results, further enhancing the accuracy of the detection.

- User expertise: The accuracy of nitrogen leak detectors also depends on the operator’s experience and knowledge. Proper training and understanding of the instrument’s capabilities ensure precise usage and interpretation of the readings.

Can Nitrogen Leak Detectors Detect all Types of Leaks?

Nitrogen leak detectors are highly effective tools used for detecting leaks in various systems. It is important to understand their capabilities and limitations when it comes to detecting different types of leaks.

1. Nitrogen leak detectors can detect most types of leaks: It is commonly asked, “Can nitrogen leak detectors detect all types of leaks?” Nitrogen is commonly used as a tracer gas for leak detection because it is non-toxic, non-flammable, and readily available. It can be used to detect leaks in both gas and liquid systems, making it versatile for a wide range of applications.

2. There are some limitations: While nitrogen leak detectors can detect a wide variety of leaks, including all types of leaks, there are certain types of leaks that may be more challenging to detect. For example, leaks that are very small or have slow leak rates may be more difficult to detect with a nitrogen leak detector. Leaks in certain materials that have low permeability or high internal pressure may also pose challenges for detection.

3. Factors affecting detection: It is important to consider the keyword, “Can nitrogen leak detectors detect all types of leaks?” The sensitivity of a nitrogen leak detector can vary depending on factors such as the concentration of nitrogen used, the size of the leak, and the distance between the leak and the detector. It is important to consider these factors and adjust the detection parameters accordingly to enhance the accuracy of leak detection.

4. Enhancing detection capabilities: To improve the chances of detecting leaks and answer the question, “Can nitrogen leak detectors detect all types of leaks?” it is recommended to conduct leak tests in a controlled environment with adequate ventilation. This can help to reduce background noise and interference, enabling better detection of leaks.

5. Regular maintenance and calibration: To ensure optimal performance, nitrogen leak detectors should be regularly maintained and calibrated. This will help to maintain accuracy and reliability in leak detection.

Are Nitrogen Leak Detectors Safe to Use?

Nitrogen leak detectors are safe to use when proper precautions and guidelines are followed. Here are some key points to consider regarding the safety of nitrogen leak detectors:

- Safety Measures: Nitrogen leak detectors are designed with safety features to prevent accidents. They are equipped with alarms and alerts to notify users in case of any malfunction or danger.

- Non-Toxic: Nitrogen gas itself is non-toxic, which makes it a safe option for leak detection. It does not pose any immediate health risks to users.

- No Harmful Residues: Nitrogen leak detectors do not leave behind any harmful residues or by-products during the detection process. This ensures a safe environment for both the users and the system being tested.

- No Risk of Combustion: Nitrogen is an inert gas, meaning it does not react with other substances or support combustion. This eliminates the risk of fire or explosion during leak detection.

- Proper Ventilation: It is important to ensure adequate ventilation when using nitrogen leak detectors. This helps to maintain a safe working environment by preventing the buildup of nitrogen gas in confined spaces.

- Training and Knowledge: Users should be properly trained on the correct usage and safety guidelines of nitrogen leak detectors. This includes understanding the equipment, following operating procedures, and knowing how to interpret the readings accurately.

Nitrogen leak detectors are safe to use when operated correctly and following safety protocols. By ensuring proper ventilation, training, and maintenance, users can confidently utilize nitrogen leak detectors for effective and safe leak detection purposes.

Is Nitrogen Gas a Safe Gas?

Nitrogen gas is generally considered to be a safe gas because it is non-toxic, colorless, odorless, and non-flammable. However, nitrogen gas can displace oxygen in the air, leading to a lack of oxygen and potentially causing asphyxiation if inhaled in large amounts in a poorly ventilated area. Therefore, it is important to handle nitrogen gas with caution and to use appropriate safety measures when working with it.

Facts About Nitrogen Leak Detection

- ✅ Nitrogen leak detectors are used to detect elevated levels of nitrogen gas.

- ✅ Nitrogen leak detectors are important for nitrogen storage, nitrogen purge systems, and nitrogen personal protection due to oxygen depletion.

- ✅ There are various types of nitrogen leak detectors available on the market, including electrochemical and zirconia sensor-based analyzers.

- ✅ Some reputable brands of nitrogen leak detectors include Nitrogen Gas Leak Detector, Nitrogen Gas Leak Monitor, and Nitrogen Portable Gas Detector for Personal Protection.

- ✅ Nitrogen leak detectors are used to check lines, joints, connectors, valves, and spigots for nitrogen leaks.

Frequently Asked Questions

1. How does a nitrogen leak detector work?

A nitrogen leak detector uses an electrochemical oxygen sensor to detect elevated levels of nitrogen gas. The sensor measures the concentration of oxygen in the air, and when oxygen levels decrease, it indicates the presence of nitrogen gas.

2. Do nitrogen gas detectors require pump air for sampling?

Yes, nitrogen gas detectors require pump air for point sampling at specific locations. This ensures accurate detection of nitrogen leaks in lines, joints, connectors, valves, and spigots.

3. Are there options for continuous oxygen monitoring with nitrogen gas detectors?

Yes, for 24/7 nitrogen leak monitoring, stationary nitrogen gas leak monitors can be used. These monitors continuously measure oxygen levels to ensure worker safety and compliance with safety regulations.

4. Can nitrogen gas detectors be used for personal protection?

Yes, portable nitrogen gas detectors are designed for personal protection. They can be worn on a person’s shirt, belt, or bag and continuously monitor nitrogen and oxygen depletion levels. These detectors have alarms to warn of dangerous situations.

5. What are the key features of the FORENSICS DETECTORS FD-600-N2 nitrogen gas detector?

The FORENSICS DETECTORS FD-600-N2 nitrogen gas detector features a high-quality electrochemical oxygen sensor for accurate detection. It has a color screen, graph functions, and data-logging capabilities. The detector is water, dust, and explosion resistant, with USB recharging and real-time data acquisition.

6. Are nitrogen gas detectors suitable for detecting nitrogen gas leaks in cryotherapy spas?

Yes, nitrogen gas detectors are recommended for cryotherapy spas, especially in small and poorly ventilated rooms. They help ensure the safety of individuals by monitoring oxygen levels and detecting any nitrogen gas leaks.

How often should I test or calibrate my Nitrogen Leak Detector?

It is best to bump test before using the Nitrogen leak detector. Calibration should be performed every 6 to 12 months. Calibration can be done by the Forensics Detectors lab or can be performed by the customer following our calibration tutorials. Items required are:

Calibration T-piece & Tubing

Calibration Gas (N2)

Calibration Gas Regulator (C10)

Maintenance Schedule for Nitrogen Leak Detectors?

It is recommended the following schedule for your nitrogen leak detector. For those working in dangerous confined spaces, we recommend bump testing daily. For R&D where accuracy is of utmost importance, we recommend calibration daily otherwise 6 to 12-month periods are OK. In general, however, the tests and schedules that are important to ensure, operation, accuracy, and safety include the:

- Bump Testing (weekly to monthly, sometimes even daily)

- Calibration Schedule (every 6 or 12 months)

- Replacement Schedule (2-3 year sensor replacement)

Conclusions

A nitrogen leak detector is a tool designed to detect the presence of nitrogen leaks in a system or environment by identifying oxygen leaks. In certain cases, an actual oxygen leak detector or an inert gas detector such as argon or helium may be necessary.

Technicians and engineers in refrigeration, cryotherapy, packaging, the food industry, the medical industry, and welding use nitrogen leak detectors. These detectors are frequently equipped with audible and visual alarms to notify the user of a leak.

To ensure their accuracy and reliability, regular maintenance and calibration of nitrogen leak detectors are essential.

The Author

Dr. Koz resides in the Palos Verdes Peninsula in Los Angeles, California. He is a subject matter expert on gas leak detectors, gas sensor technology, gas detectors, gas meters, and gas analyzers. He has been designing, building, manufacturing, and testing toxic gas detection systems for over 20 years. Every day is a blessing for Dr. Koz. He loves to help customers solve their unique problems.

Email: drkoz@gasleakdetector.com

Phone: +1 424-341-3886