Contents

A gas leak detector works by detecting the presence of combustible gases in the air and alerting the user. Gas leak detectors are essential safety devices that can prevent accidents and protect lives.

They work by detecting the presence of combustible gases, such as natural gas or propane, in the air. Gas leak detectors utilize sensors that are specifically designed to detect the particular gases they are set to detect. These sensors use various technologies, such as electrochemical, semiconductor, or infrared, to measure the concentration of gases in the surrounding air.

When a gas leak is detected, the detector emits an audible and/or visual alarm to alert the user, enabling them to take immediate action and prevent potential hazards. Gas leak detectors are widely used in residential, commercial, and industrial settings to ensure the safety of individuals and property.

Types Of Gas Leak Detectors

Gas leak detectors are devices designed to detect the presence of potentially hazardous gases, such as natural gas and propane, in residential, commercial, and industrial settings. These detectors work by monitoring the air for abnormal levels of gas, emitting a loud alarm to alert occupants and prompt action to prevent accidents or leaks.

When it comes to gas leak detectors, two main types are commonly used – portable and fixed gas leak detectors. These detectors serve the same purpose of detecting the presence of gas leaks in buildings or enclosed spaces, but they differ in terms of their design and functionality. Let’s take a closer look at each type.

Portable Gas Leak Detectors

Portable gas leak detectors are handheld devices that are designed to detect gas leaks in various environments. These lightweight and compact detectors can be easily carried around, making them suitable for use in different locations.

Fixed Gas Leak Detectors

Unlike portable detectors, fixed gas leak detectors are permanently installed in specific areas to monitor gas levels continuously. These detectors are typically connected to a central control panel or an alarm system, which alerts the occupants of the building if there is a gas leak detected. Fixed detectors are commonly used in industrial settings or areas where gas leaks are more likely to occur.

These gas leak detectors work by utilizing different sensing technologies to detect the presence of gas. Some common types of gas sensors used in these detectors include electrochemical sensors, infrared sensors, and semiconductor sensors. Each sensor type has its own advantages and limitations, allowing for effective and reliable gas leak detection.

Working Principles Of Gas Leak Detectors

Gas leak detectors are essential safety devices that help detect the presence of potentially dangerous gas leaks. These detectors operate on various working principles, each designed to detect specific types of gases. Understanding the working principles of gas leak detectors is crucial for choosing the right detector for your needs. In this blog post, we will delve into three common working principles used in gas leak detectors: catalytic bead sensors, infrared sensors, and ultrasonic sensors.

Catalytic Bead Sensors

Catalytic bead sensors are widely used in gas leak detectors to detect flammable gases like methane, propane, and butane. These sensors contain two heated beads made of platinum wire coated with a catalyst material, such as palladium.

When flammable gas comes into contact with the sensor, it undergoes a catalytic combustion reaction, producing heat and raising the temperature of the beads. This increase in temperature leads to a change in electrical resistance, which is measured by the gas leak detector. If the resistance exceeds a predetermined threshold, an alarm is triggered, alerting the presence of a gas leak.

Infrared Sensors

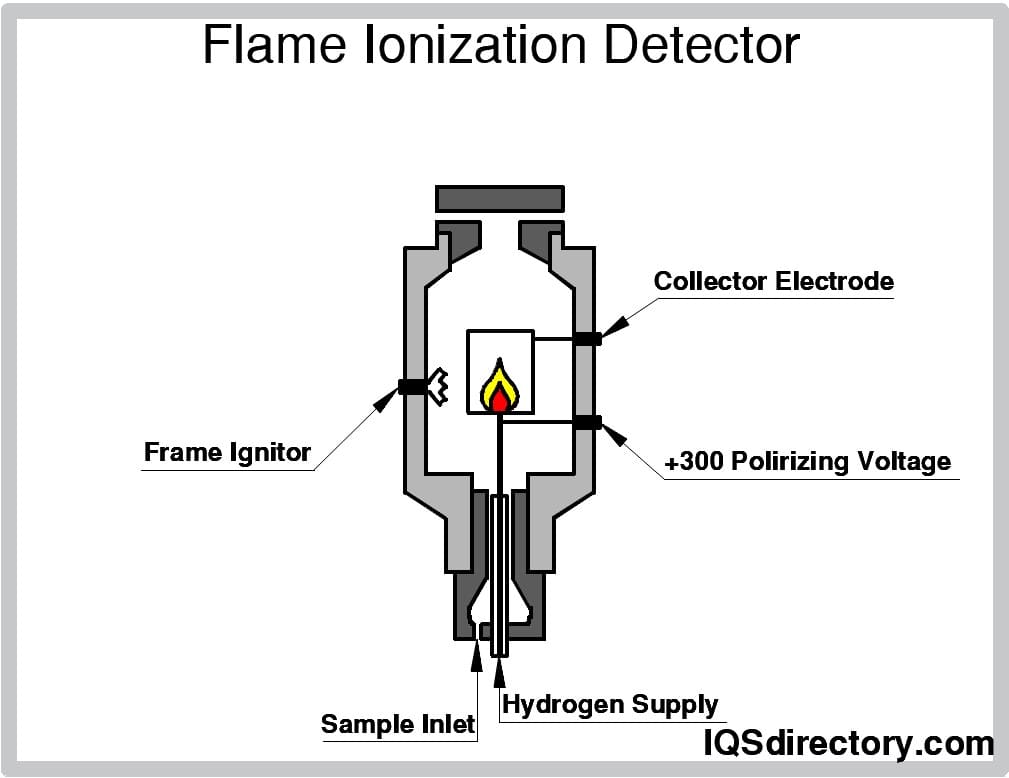

Infrared sensors are commonly used in gas leak detectors to detect a wide range of gases, including carbon dioxide, methane, and volatile organic compounds (VOCs). These sensors work on the principle of absorption of infrared radiation by the target gas. In a gas leak detector equipped with infrared sensors, infrared light is emitted by a source and directed towards a detector.

When gas molecules are present in the path of the light, they absorb specific wavelengths of infrared radiation. The detector measures the decrease in infrared intensity caused by gas absorption, and based on this measurement, it identifies and signals the presence of a gas leak.

Ultrasonic Sensors

Ultrasonic sensors are employed in gas leak detectors to detect pressurized or high-velocity gas leaks. These sensors work on the principle of sound waves. In a gas leak detector equipped with ultrasonic sensors, an ultrasonic sound wave is emitted into the surrounding environment. If there is a gas leak, the escaping gas causes turbulence in the air.

This turbulence leads to changes in the ultrasonic sound wave’s frequency or amplitude. The gas leak detector picks up these changes using a sensitive receiver, and upon detecting abnormal variations, it activates an alarm to notify the presence of a gas leak.

Frequently Asked Questions

How Does A Gas Leak Detector Work?

Gas leak detectors work by sensing the presence of gas in the air. They utilize sensors that detect different types of gases and trigger an alarm when it reaches a certain concentration. This helps to alert individuals to potential gas leaks so that they can take necessary precautions or call for help.

Conclusion

A gas leak detector is a vital tool for detecting and alerting us of potential gas leaks. By utilizing advanced sensors, these detectors can identify and measure the presence of gas in the air, ensuring the safety of our homes and workplaces.

Investing in a reliable gas leak detector is a smart and responsible choice for anyone concerned about gas leaks and the associated risks they pose. Stay safe and secure with a gas leak detector by your side.