Contents

- Methods Of Hydrogen Leak Detection

- Visual Inspection

- Electronic Sensors And Detectors

- Gas Chromatography

- Challenges And Safety Measures

- Challenges In Detecting Hydrogen Leaks

- Safety Measures For Hydrogen Gas Stations

- Frequently Asked Questions

- How Does Hydrogen Leak Detection Work?

- Why Is Hydrogen Gas Station Leak Detection Important?

- What Are The Benefits Of Hydrogen Leak Detection Systems?

- How Accurate Are Hydrogen Leak Detection Systems?

- Conclusion

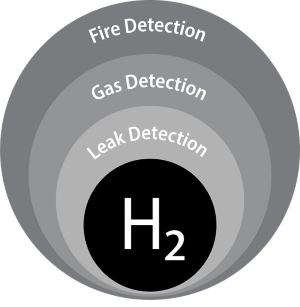

Hydrogen leak detection is crucial for hydrogen gas stations to ensure safety and prevent accidents. This process involves the use of advanced sensing technologies to identify even the smallest leaks in the hydrogen infrastructure.

Detecting leaks promptly allows for immediate action, minimizing the risk of explosions or fires. Additionally, regular leak detection helps maintain the integrity of the gas stations, ensuring the smooth operation of refueling processes.

By implementing effective leak detection systems, hydrogen gas station operators can ensure the safety of their employees, customers, and the surrounding environment.

These systems play a vital role in promoting the widespread adoption of hydrogen fuel as a sustainable and clean energy source.

Credit: www.researchgate.net

Methods Of Hydrogen Leak Detection

Hydrogen leak detection methods are crucial for ensuring the safety of hydrogen gas stations. Various techniques, such as mass spectrometry and infrared imaging, are used to detect leaks and prevent potential hazards.

Hydrogen gas stations, being the backbone of the hydrogen fuel infrastructure, require vigilant monitoring to ensure safety and prevent leaks. In this blog post, we will explore the various methods of hydrogen leak detection that operators can employ to maintain the integrity of their facilities. From visual inspection to gas chromatography, each technique plays a vital role in identifying and addressing potential leaks before they escalate into serious hazards.

Visual Inspection

Visual inspection is the simplest and most straightforward method of detecting hydrogen leaks. By carefully examining the equipment, pipes, fittings, and valves, operators can visually identify any signs of leakage, such as discoloration or stains caused by escaping hydrogen gas.

This method not only allows for quick detection but also provides an opportunity to spot other maintenance issues that might affect the overall functioning of the station.

Electronic Sensors And Detectors

While visual inspection is effective, it may not be sufficient to capture all potential leaks. This is where electronic sensors and detectors come into play. These devices are designed specifically to detect hydrogen gas concentration in the environment and trigger an alarm when it exceeds a predefined threshold.

Equipped with highly sensitive semiconductor technology, these sensors can swiftly identify even the tiniest hydrogen leaks, ensuring the safety of both station operators and the surrounding community.

Gas Chromatography

When precise measurements are paramount, gas chromatography emerges as a reliable method for hydrogen leak detection. This technique involves collecting hydrogen gas samples from various parts of the station and analyzing them using specialized equipment.

Gas chromatography not only detects the presence of hydrogen but also quantifies the concentration accurately. By providing precise data, this method enables station operators to make informed decisions regarding leak remediation and preventive measures.

To summarize, when it comes to hydrogen leak detection at gas stations, there are several methods available. Visual inspection serves as a primary and initial line of defense, allowing operators to identify visible signs of leaks promptly.

Electronic sensors and detectors add an extra layer of security by continuously monitoring hydrogen gas concentration in the environment. For precise measurements and analysis, gas chromatography emerges as a reliable technique, facilitating informed decision-making in leak remediation and preventive maintenance.

By implementing an integrated approach that combines these methods, hydrogen gas stations can maintain safety and ensure the efficient operation of their infrastructure.

Challenges And Safety Measures

Hydrogen is a promising alternative fuel that is increasingly being used in vehicles and power generation. However, the safe handling and storage of hydrogen gas is of paramount importance. One of the key concerns for hydrogen gas stations is the detection of hydrogen leaks.

Challenges In Detecting Hydrogen Leaks

Detecting hydrogen leaks can be challenging due to the unique properties of hydrogen gas. Here are some of the key challenges:

- Highly flammable: Hydrogen has a low ignition energy, making it highly combustible. This means that even the tiniest amount of leaked hydrogen can result in a significant fire hazard.

- Invisible and odorless: Hydrogen is both colorless and odorless, which means leaks cannot be detected through our senses alone. This lack of detectability increases the difficulty of identifying leaks promptly.

- Low molecular weight: Hydrogen has the lowest molecular weight among all gases, which makes it highly diffusive. This rapid diffusion can make it difficult to pinpoint the exact location of a leak.

- Pressure differentials: Hydrogen gas is often stored at high pressure, which can lead to leaks forming at weak points such as joints, fittings, and valves. Detecting these leaks can be a challenge due to the presence of multiple potential leak sources.

Safety Measures For Hydrogen Gas Stations

To ensure the safety of hydrogen gas stations, various measures can be implemented:

- Remote monitoring: Installing remote monitoring systems can provide real-time data on hydrogen storage and distribution infrastructure, enabling operators to quickly identify and respond to any potential leaks.

- Leak detection sensors: Utilizing advanced leak detection sensors that are specifically designed for hydrogen gas can enhance the accuracy and speed of leak detection.

- Automatic shut-off valves: Incorporating automatic shut-off valves in the event of a leak can help prevent the release of more hydrogen and limit the potential for a hazardous situation.

- Proper ventilation: Ensuring adequate ventilation in hydrogen storage and dispensing areas can help disperse any leaked hydrogen and minimize the risk of ignition.

- Regular maintenance: Regular inspections, maintenance, and testing of the hydrogen storage and distribution systems are crucial for ensuring the integrity of the infrastructure and preventing leaks.

By addressing the challenges associated with detecting hydrogen leaks and implementing the necessary safety measures, hydrogen gas stations can continue to provide a clean and efficient fueling solution with minimal risks.

Frequently Asked Questions

How Does Hydrogen Leak Detection Work?

Hydrogen leak detection uses specialized sensors to detect the presence of hydrogen gas. These sensors can identify even the smallest leaks, allowing for prompt action to prevent accidents. Through advanced technology, hydrogen leak detection ensures the safety and efficiency of hydrogen gas stations.

Why Is Hydrogen Gas Station Leak Detection Important?

Hydrogen gas station leak detection is crucial for several reasons. First, it helps ensure the safety of workers and the public by preventing potential hydrogen leaks. Second, it helps maintain the integrity of equipment and infrastructure, minimizing the risk of costly damage.

Lastly, it allows for efficient operation and reduces hydrogen waste.

What Are The Benefits Of Hydrogen Leak Detection Systems?

Hydrogen leak detection systems offer numerous benefits. They provide early warning of potential leaks, allowing for immediate action to prevent accidents. By promptly identifying and addressing leaks, these systems enhance safety, prevent damage, and reduce downtime. Additionally, they contribute to the overall efficiency and sustainability of hydrogen gas stations.

How Accurate Are Hydrogen Leak Detection Systems?

Hydrogen leak detection systems are highly accurate, capable of detecting even small leaks at low concentrations. With advanced sensing technology, these systems can provide precise and reliable measurements, ensuring the safety and integrity of hydrogen gas stations. Regular calibration and maintenance further enhance their accuracy and effectiveness.

Conclusion

Hydrogen leak detection plays a crucial role in ensuring the safe operation of hydrogen gas stations. By employing advanced technologies and innovative solutions, the industry can effectively mitigate the risks associated with hydrogen leaks. Implementing robust detection systems not only protects the environment but also safeguards the overall infrastructure.

As the demand for hydrogen energy continues to grow, it is imperative to prioritize safety through reliable leak detection methods. Stay ahead of the curve and embrace the future of clean energy with hydrogen gas stations.