Contents

- Methods Of Hydrogen Leak Detection

- Visual Inspection

- Pressure Decay Testing

- Mass Spectrometry

- Challenges And Solutions

- Challenges Of Hydrogen Leak Detection

- Innovations In Leak Detection Technology

- Frequently Asked Questions

- How Does Hydrogen Leak Detection Ensure Rocket Reliability?

- Why Is Hydrogen Leak Detection Essential For Rocket Launches?

- What Are The Commonly Used Methods For Hydrogen Leak Detection?

- How Can Hydrogen Leaks Affect Rocket Reliability?

- Conclusion

Hydrogen leak detection is crucial for improving rocket reliability. This article explores the importance of detecting hydrogen leaks in rockets and discusses various methods used for ensuring safety and enhancing overall performance.

It also highlights the significance of reliable leak detection systems in reducing the risk of catastrophic failures during rocket launches.

By implementing effective hydrogen leak detection measures, space agencies, and rocket manufacturers can minimize the chances of leaks, maintain mission success, and safeguard both astronauts and valuable payloads.

An in-depth understanding of hydrogen leak detection techniques can contribute to the continual improvement of rocket technology, making space exploration safer and more reliable.

Methods Of Hydrogen Leak Detection

Ensuring the reliability of rockets is of utmost importance in space exploration. One critical aspect of rocket reliability is the detection of hydrogen leaks. Hydrogen, being highly flammable and explosive, requires meticulous detection methods to ensure the safety and functionality of rocket systems.

Visual Inspection

Visual inspection is a straightforward yet effective method of detecting hydrogen leaks. It involves a careful and thorough examination of the rocket system, looking for any signs of hydrogen gas escaping.

This method relies on trained personnel who visually inspect the various components and connections for indicators such as discoloration, rust, corrosion, or any physical damage that could lead to leaks.

The visual inspection process can be enhanced using techniques like dye penetrant testing. In this method, a colored dye is applied to the suspected area, allowing any microscopic cracks or leaks to become visible by the contrast between the dye and the surface.

Pressure Decay Testing

Pressure decay testing is another effective method used in hydrogen leak detection for rockets. This method involves pressurizing the rocket system with hydrogen and then monitoring the pressure drop over a set period. Any decrease in pressure indicates the presence of a leak.

The sensitivity and accuracy of pressure decay testing depend on factors such as the size, location, and nature of the leak, as well as the testing equipment used.

During pressure decay testing, a tight control is maintained over external factors that could influence the pressure, such as temperature and vibration. This ensures that the pressure drop observed is solely due to the presence of a hydrogen leak within the system.

Mass Spectrometry

Mass spectrometry, a highly sensitive and precise method, is often utilized for detecting extremely small hydrogen leaks in rocket systems. This method involves capturing a sample of gas from the system and ionizing it. The ionized gas particles are then separated based on their mass-to-charge ratio, allowing the detection of even the tiniest hydrogen molecules.

Mass spectrometry provides accurate leak detection by analyzing the mass spectrometric patterns and identifying the specific hydrogen isotopes present. This method can be used to pinpoint the exact location of the leak, allowing for timely repairs and ensuring the overall reliability of the rocket system.

Each of these methods – visual inspection, pressure decay testing, and mass spectrometry – plays a crucial role in hydrogen leak detection for rocket reliability.

Challenges And Solutions

Hydrogen leak detection is crucial for ensuring rocket reliability. This challenge is addressed through advanced technologies and systems that detect and mitigate leaks, ensuring safe and efficient space exploration. Trustworthy hydrogen leak detection solutions are vital for the success of rocket missions, providing a high level of reliability and minimizing risks.

Challenges Of Hydrogen Leak Detection

Hydrogen leak detection presents unique challenges that require innovative solutions to ensure rocket reliability. The highly volatile nature of hydrogen, combined with its ability to diffuse rapidly through materials, makes it extremely difficult to detect leaks accurately and efficiently.

To maintain the highest levels of safety and prevent catastrophic failures, it is essential to overcome these challenges with cutting-edge technology and advanced detection techniques.

Innovations In Leak Detection Technology

Recent advancements in leak detection technology have revolutionized the way hydrogen leaks are identified and addressed. These innovations not only improve detection capabilities but also enhance the overall reliability of rockets. Here are some noteworthy developments:

- Laser-based Detection Systems:

New laser-based systems utilize spectroscopy to precisely analyze the composition of the surrounding atmosphere. By targeting specific hydrogen absorption or emission wavelengths, these systems can quickly identify even the tiniest leaks, allowing for prompt repairs and enhanced safety.

- Ultrasound Testing:

Ultrasound technology has emerged as a powerful tool for detecting hydrogen leaks. By emitting high-frequency sound waves, engineers can identify the distinct acoustic signature associated with hydrogen leakage. This non-invasive method provides real-time results and can be deployed in various operating conditions, contributing to overall rocket reliability.

- Nano-sensors:

Miniaturized hydrogen sensors with nano-scale components have greatly improved leak detection capabilities. These sensors can be embedded within critical system components, continuously monitoring for leaks and providing immediate feedback. The use of nano-sensors significantly reduces both the detection time and the risk of hydrogen-related incidents in rockets.

With the continuous advancement of technology, the future of leak detection holds great promise, paving the way for even better solutions in the years to come.

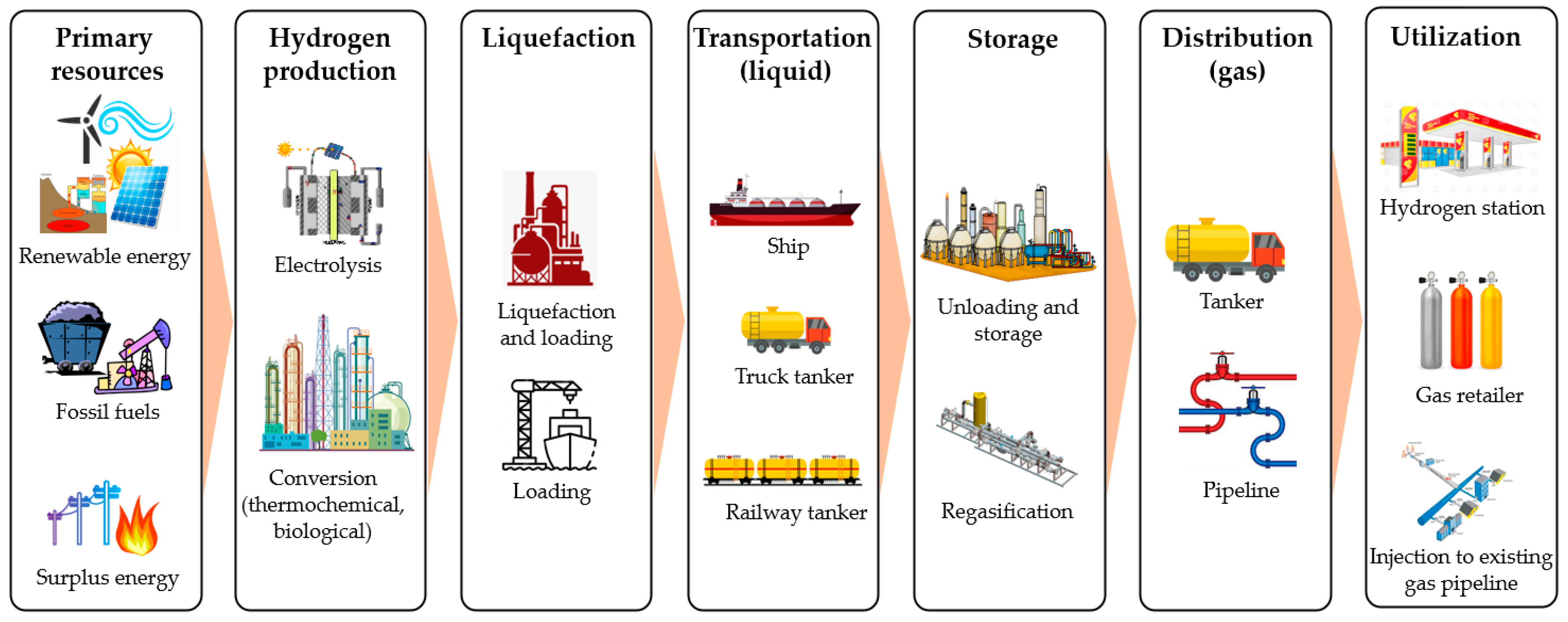

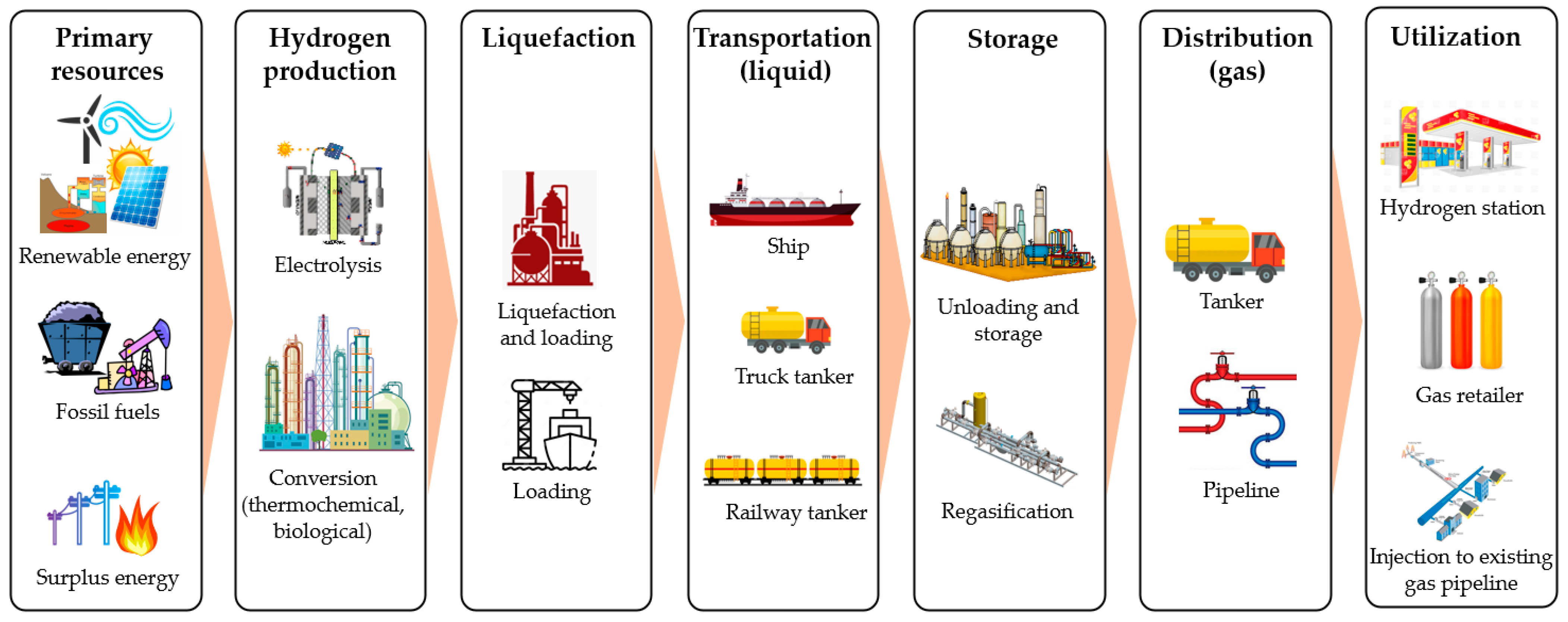

Credit: www.mdpi.com

Frequently Asked Questions

How Does Hydrogen Leak Detection Ensure Rocket Reliability?

Hydrogen leak detection plays a crucial role in maintaining rocket reliability. It identifies and locates any hydrogen leaks, preventing potential malfunctions and ensuring safe operation. By detecting leaks early on, engineers can take necessary corrective actions to enhance rocket performance and reliability.

Why Is Hydrogen Leak Detection Essential For Rocket Launches?

Hydrogen leak detection is essential for rocket launches as hydrogen serves as a vital propellant. Detecting leaks ensures the proper functioning of the propulsion system, optimizing fuel efficiency and overall rocket performance. It guarantees a safe and successful launch, reducing the risk of accidents and ensuring mission success.

What Are The Commonly Used Methods For Hydrogen Leak Detection?

There are several methods used for hydrogen leak detection, including the use of gas analyzers, sniffer probes, and tracer gases. Gas analyzers detect the presence of hydrogen in the atmosphere, while sniffer probes identify leaks by sensing hydrogen concentrations. Tracer gases, such as helium, are also employed to pinpoint leaks with precision.

These methods collectively provide comprehensive hydrogen leak detection capabilities.

How Can Hydrogen Leaks Affect Rocket Reliability?

Hydrogen leaks can significantly impact rocket reliability. They can lead to engine failures, propulsion system malfunctions, and even catastrophic incidents. Leaks can compromise fuel efficiency, resulting in reduced performance and potential mission failure. Detecting and addressing hydrogen leaks promptly is crucial to ensure the reliability and success of rocket launches.

Conclusion

To ensure optimum rocket reliability, the detection of hydrogen leaks plays a crucial role. Implementing advanced techniques and technologies for detecting leaks is paramount for ensuring the safety and efficiency of rocket operations.

By incorporating innovative methods tailored to address the unique challenges of hydrogen leaks, such as using state-of-the-art sensors and monitoring systems, rocket engineers can effectively prevent accidents and maintain the reliability of their systems.

Overall, by prioritizing hydrogen leak detection, the aerospace industry can take significant strides towards enhanced safety and space exploration advancements.